Electrical systems are critical to modern operations, powering everything from industrial facilities to residential areas. However, monitoring these systems effectively can be a challenge, especially when faults or inefficiencies develop over time.

Enter thermal imaging technology – a game-changing tool that has significantly improved electrical system monitoring.

This post dives into how thermal imaging enhances electrical maintenance, the benefits it presents, and its role in predictive maintenance efforts. Read on to discover a smarter, safer, and more efficient way to maintain electrical systems.

Why Thermal Imaging Technology Is Key

Thermal imaging, commonly associated with high-tech cameras, allows us to visualize areas of heat variation that are invisible to the naked eye.

These variations often pinpoint potentially dangerous issues like overheating components or electrical faults before they escalate.

By using thermal imaging systems, professionals are provided with highly detailed and actionable insights, making it a powerful ally in electrical system management.

Paired with solutions such as Systems with Intelligence, it can offer a fully integrated approach to safeguarding electrical performance.

Addressing Common Electrical Challenges

Maintaining electrical systems involves managing several risks and challenges that could disrupt operations. Some of the common issues that thermal imaging helps address include:

- Overheating Components

High temperatures often signal potential malfunctions. Thermal cameras detect hotspots in circuits, wiring, or transformers in seconds, allowing maintenance teams to address overheating proactively before it leads to equipment failure.

- Aging Infrastructure

Components within electrical systems degrade over time, decreasing their efficiency. Early identification of wear and tear using thermal imaging reduces the risk of unplanned outages or safety hazards.

- Invisible Energy Losses

Energy loss within electrical systems can be subtle yet costly. Using thermal imaging, professionals can detect subtle inefficiencies like poor insulation or loose connections that could waste energy and increase operational costs.

How Thermal Imaging Fits Into Predictive Maintenance

Predictive maintenance is a proactive technique that anticipates problems before they occur, reducing downtime and maintenance costs. Thermal imaging plays a fundamental role in this practice by offering real-time insights and advanced monitoring capabilities.

Real-Time Thermal Monitoring

Thermal imaging systems provide real-time data that continuously observes and reports the status of electrical components. Such monitoring ensures that irregular patterns or temperatures are flagged immediately, minimizing operational risks.

Cost and Time Efficiency

Traditional maintenance requires manual inspections, which are time-consuming and labor-intensive. Thermal imaging transforms this approach by automating the detection process.

Maintenance teams can then schedule targeted repairs instead of widespread or unnecessary interventions, saving considerable resources.

Enhanced Reliability With Predictive Strategies

Thermal monitoring systems feed critical data into predictive algorithms, making it easier to build accurate maintenance schedules. Over time, these insights optimize performance while extending the lifespan of components.

Benefits of Electrical System Monitoring

Improved Safety

Thermal cameras can detect potentially hazardous conditions such as sparks or electrical arcs before they become full-fledged safety risks. Prevention efforts reduce the likelihood of costly shutdowns or dangerous accidents.

Extended Equipment Life Cycle

By catching faults early, repairs can be more efficient, preventing wear and tear on connected equipment. This approach not only increases operational reliability but also extends the life span of key infrastructure.

Proactive Problem Detection

Thermal imaging significantly improves problem-detection accuracy. Gaps or anomalies that would otherwise go unnoticed can be addressed before they develop into larger issues, further improving downtime management.

Eco-Friendly Outcomes

Minimizing energy losses is both cost-effective and environmentally responsible. By detecting and resolving inefficiencies with thermal imaging, energy wastage is effectively curtailed, aligning operational practices with sustainability goals.

Applications in Diverse Sectors

Thermal imaging technology has gained traction across various industries that rely heavily on electrical systems.

Industrial Facilities

Thermal imaging is widely used in industrial settings to monitor machinery, circuit loads, and production equipment. Manufacturing plants, for example, often integrate thermal systems to detect faults quickly, which ensures process continuity.

Power Grids

Power systems like substations and transformers are prone to overheating, especially under heavy loads. Thermal cameras can quickly scan large areas, allowing grid operators to maintain the flow of power with minimal interruptions.

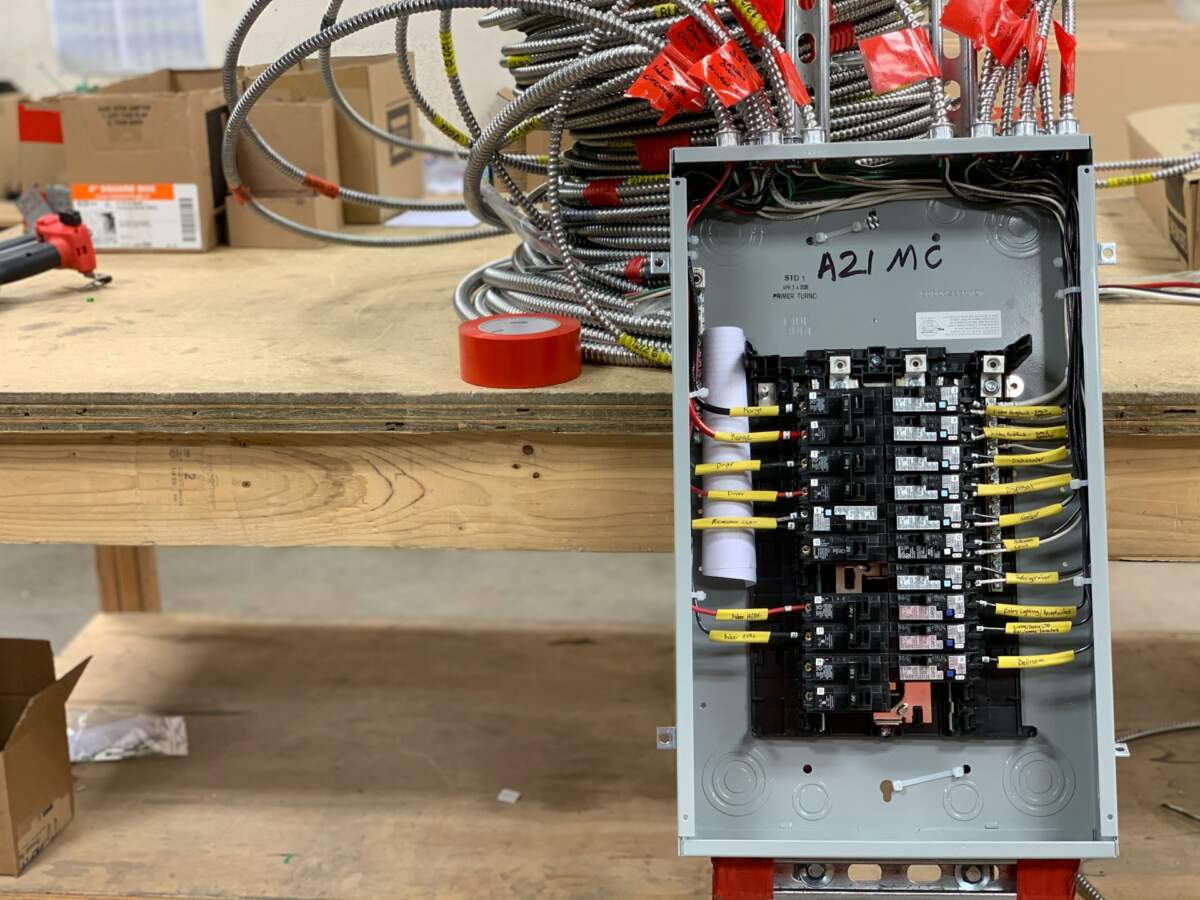

Commercial and Residential Buildings

For commercial applications, thermal imaging helps in identifying hidden electrical wiring issues within walls or ceilings. This makes it invaluable for contractors and engineers tasked with ensuring the safety and efficiency of building infrastructure.

The Future of Electrical Maintenance With Thermal Imaging

Thermal imaging technology is not just a tool but a window into the future of modern electrical maintenance.

With AI and IoT developments further expanding capabilities, we can expect even smarter systems to emerge – ones that integrate seamlessly into larger monitoring frameworks, providing an unprecedented level of insight.

For businesses or facilities managing large-scale electrical infrastructures, adopting systems that integrate tools like thermal imaging is a move toward safer, more sustainable, and future-ready maintenance practices.

What You Can Do Next

If you’re looking to bolster your electrical system monitoring and enhance operational security, consider incorporating advanced tools like thermal cameras into your strategy.

Pairing predictive maintenance with cutting-edge systems can ensure efficiency and reliability long-term. Explore solutions like Systems with Intelligence and see the opportunities smarter monitoring can unlock for you today.